The Future of Footwear at Footwearology Lab

I spent two weeks in Barcelona at Footwearology Lab to learn how 3D printing and knitting will change footwear forever

Seven months ago I enrolled in the Loco for Local course at Footwearology, a unique academy situated in the middle of Barcelona that focuses on educating the next generation of footwear designers. I had already followed a variety of online courses that they offered on 3D modelling for footwear and I had met the crew at the event they hosted together with Desma back in September of last year where different speakers presented the future of footwear. Their new Loco for Local course was my chance to visit their lab, work directly with the experts and witness the craziness first hand. And, let me tell you, it was crazy.

The course focuses on the local manufacturing methods for footwear (hence the name of the course). More specifically, I was going to learn how to use 3D printing and knitting. In a series of online courses we were taught the basics of modular footwear design and how to design for the manufacturing methods that we were going to use. For half a year, I was sketching, creating 3D models and working on different concepts. Together with the help of Kedar Benjamin, one of their computational design specialists, I was able to further progress my 3D footwear modelling skills and turn my concept into a 3D model that could be printed.

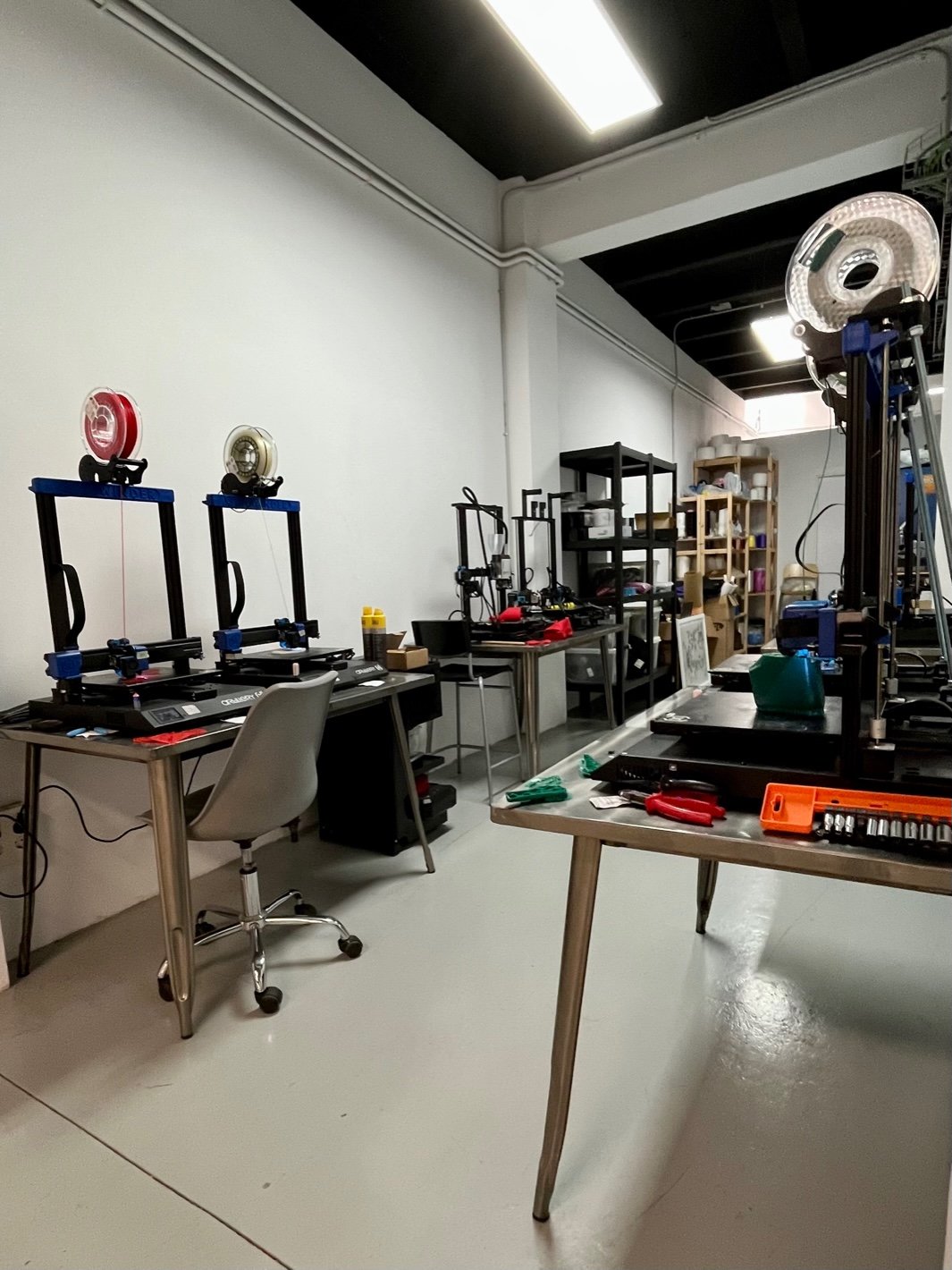

Then it was time to come over to the lab and start making some prototypes! For two weeks, I was helped by Luis Bugin, Marina Aperribay and Jordi Montaner to turn my ideas into reality. Four years ago I was still browsing through every instagram and Behance profile that did something around sneakers and 3D printing, but it still seemed so far away. I did some experiments with the printers at university, but it was far from what it should be. But 3D printing kept growing in the footwear industry. And I am glad that in these past months and especially the two weeks at Footwearology Lab, I was finally able go from initial idea all the way to having a 3D printed shoe that could be worn right now! Or at least after I have printed the left shoe as well.. I ordered my printer, so it won’t take long!

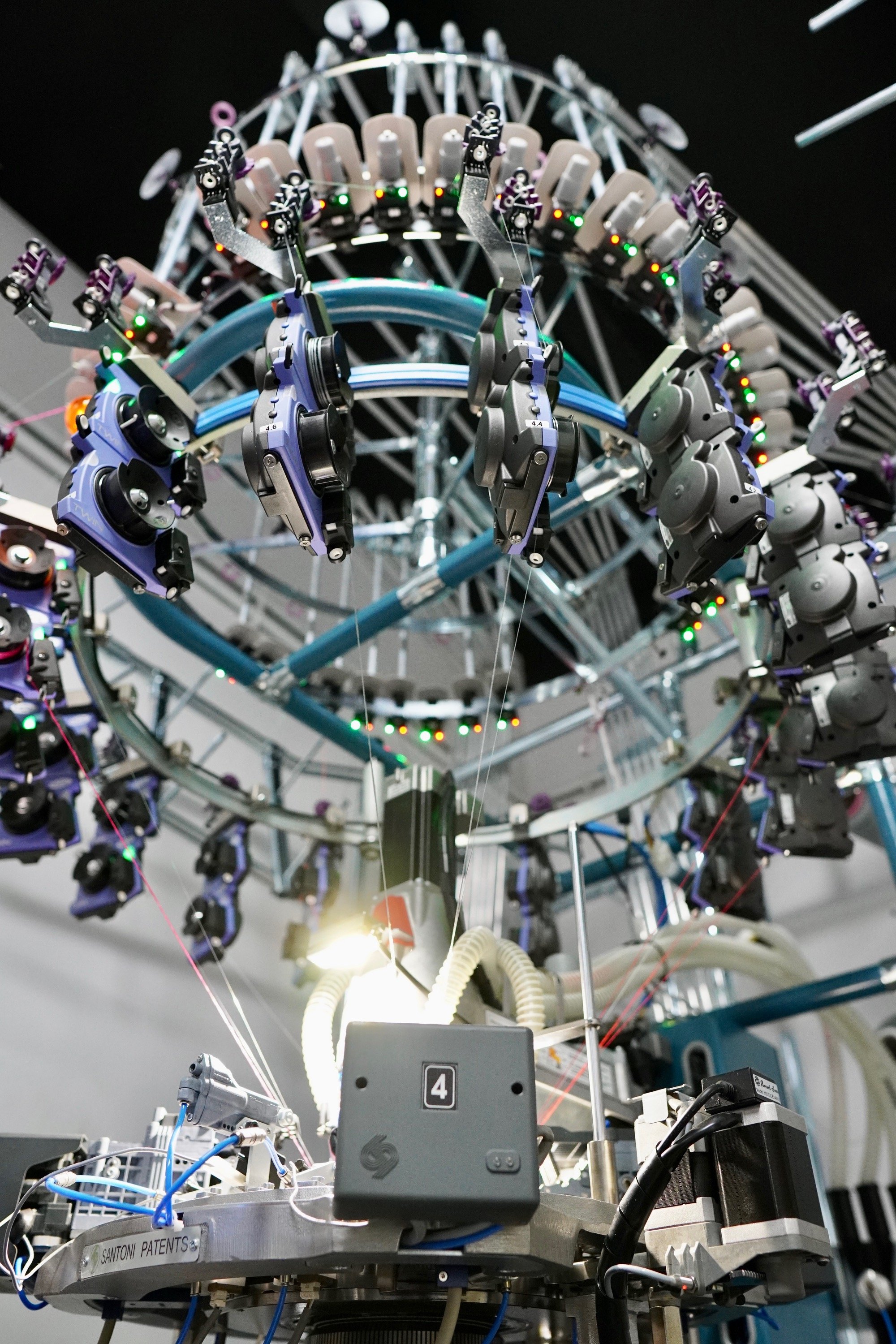

After week 1, I pretty much had my 3D printed shoe in my hands. In the second week I decided to focus on the 3D knitting techniques. We were taught the core principles of using the software and flatbed 3D knitting machine and I created some samples. After playing around with pixels and creating graphics, I wanted to experiment with creating 3D shapes into textile using 3D printed molds and the melting yarn between the fabric. This was a new technique that the lab had recently started doing the first experiments with.

I have learned a lot during my two weeks at Footwearology Lab and will be continuing my research into these groundbraking technologies for creating the footwear of tomorrow. These technologies will not only have a big impact on how footwear is produced with respect for people and planet, but it also brings new opportunities for creating custom footwear for everyone and radically changing the way footwear looks. I think the footwear industry in five to ten years will be unrecognizable from what it is today and what it has been for the past hundred years! Get ready.